Anionic PAM Emulsion For Sludge treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

1. Anionic PAM sludge polymer is used as anionic PAM emulsion for sludge pretreatment process.

2.Emulsion flocculant is used as emulsion flocculant polymer to treat the sludge(emulsion PAM sludge).

3.Using anionic PAM emulsion to treat sludge is a comprehensive solution(Anionic PAM sludge with PAC).

Download

Anionic PAM emulsion polyacrylamide has the following main applications in emulsion PAM sludge pretreatment:

1) Sludge dewatering when using anionic PAM sludge to treat the sludge: Through charge neutralization and adsorption bridging effects, fine particles in the sludge are aggregated to form larger flocs, increasing the sedimentation rate of the sludge, which is conducive to subsequent dewatering treatment using emulsion flocculant. The negative charges on the molecules of emulsion flocculant neutralize the positive charges on the surface of sludge particles, reducing the repulsive force between the particles. At the same time, the long chains of emulsion flocculant form bridges between the particles, connecting them. Emulsion flocculant can greatly improve the sludge dewatering efficiency, reduce the moisture content in the sludge and form a drier sludge cake, facilitating subsequent treatment and disposal, such as landfill, incineration or resource utilization. For example, in the sludge dewatering treatment of municipal sewage treatment plants, after using anionic PAM emulsion polyacrylamide, the moisture content of the sludge cake is significantly reduced. The specific dosage of anionic PAM emulsion varies depending on the properties of the sludge (such as sludge type, organic matter content, particle size, etc.) and the treatment process. Generally, for every ton of sludge (dry weight) treated, the dosage of anionic PAM emulsion polyacrylamide is about 1.8--9.0 kilograms, but the optimal dosage of emulsion PAM sludge product needs to be determined through experiments in practical applications.

2) Sludge conditioning: Anionic PAM sludge polymer can improve the filtration performance of the sludge, reduce the specific resistance of the sludge, make the sludge pass through the filter cloth or filter screen more easily during the filtration process and improve the filtration efficiency. For example, in some industrial wastewater pretreatment processes, the filtration speed of the sludge conditioned by anionic emulsion flocculant on the plate and frame filter press is significantly accelerated.

3) Improving sludge sedimentation performance: Accelerate the sedimentation rate of the sludge, so that the sludge can complete the sedimentation in a shorter time, reducing the footprint and residence time of the sedimentation tank. For some sludge containing a large number of fine particles, after adding anionic PAM sludge polymer, the sedimentation effect is significantly improved.

4) Sludge drying: In the sludge drying process, emulsion PAM sludge polymer can play an auxiliary role. Anionic PAM sludge polymer can form a strong binding force between the sludge particles, enhance the integrity and stability of the sludge, prevent problems such as scattering and flying of the sludge during the drying process and help improve the drying efficiency and the quality of the dried sludge.

5) Sludge incineration: For sludge that needs to be incinerated, anionic PAM sludge polymer can help increase the calorific value of the sludge, make it easier to burn and at the same time reduce the soot and harmful gases generated during the combustion process. By interacting with the organic matter and moisture in the sludge, the sludge can burn more fully during incineration, reducing environmental pollution.

When using emulsion flocculant to treat sludge, the following matters need to be noted:

It is necessary to select emulsion PAM sludge polymer to treat sludge with the appropriate ionic degree and molecular weight according to the properties and treatment requirements of the sludge. Different types of sludge have different requirements for anionic PAM emulsion polymer. For example, for sludge with a high content of organic sludge, a product with a higher ionic degree may be required to achieve a better treatment effect.

Accurately control the dosage of emulsion PAM sludge polymer for sludge pretreatment. Insufficient dosage cannot achieve the desired treatment effect, while excessive dosage may lead to increased costs and may also increase the difficulty of sludge treatment, such as causing the sludge to be overly viscous and other problems. At the same time, ensure full mixing with the sludge to achieve a uniform flocculation effect. Uneven mixing may lead to poor flocculation effects in local areas, affecting the overall treatment effect.

Pay attention to the storage conditions of the product, avoid direct sunlight, humidity and other environments to prevent the emulsion flocculant from deteriorating. The storage temperature is generally between 5--35℃ and the storage time should not be too long.

Industry-specific attributes:

| Name | Anionic PAM Emulsion | |||

| Application | PAM Emulsion for sludge pretreatment | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes:

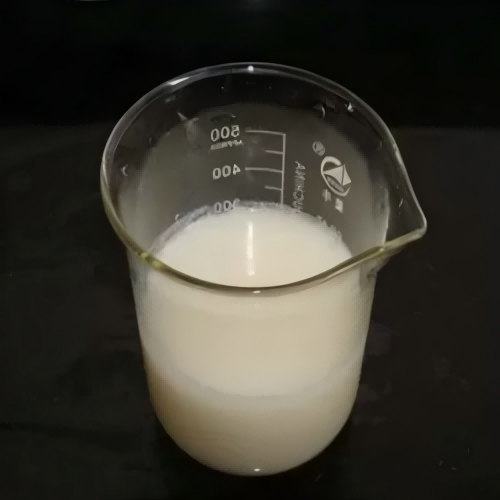

| Appearance | Milky,White Viscous Emulsion flocculant | |||

| Solid Content | 40% | |||

| Molecular Weight10*6 | 15~30 | |||

| Specific Granvity(25℃) | 1.0 | |||

| Insoluble Substance(%) | 0.1 | |||

| PH Value | 6.5~7.5 | |||

| Dissolving Time,min | <30 | |||

| Anionic charge(%) | 30 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 12 | |||

Supply Ability:

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time:

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |