Chemical Polydadmac For Water Treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

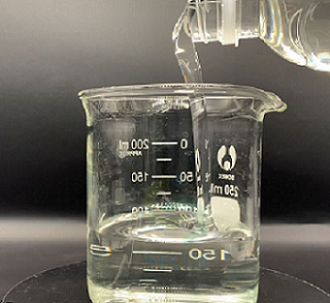

40%chemical polydadmac emulsion has been widely applied as a polydadmac coagulant in drinking water and sewage treatment.

Chemical polydadmac products are a high molecular weight product and are 40%polydadmac chemicals (Polydadmac 40).

Download

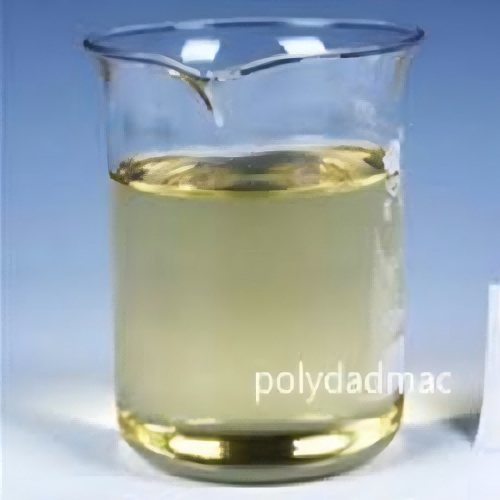

Polydadmac chemicals is a kind of colorless to white viscous liquid,among which the viscosity is different with the activate content changing.

The treatment effect of 40%chemical polydadmac emulsion varies at different temperatures: 1. The effects of using polydadmac chemicals under low-temperature conditions:In a low-temperature environment, the molecular movement speed of polydadmac 40 slows down and the contact and reaction speeds with oil droplets, solid particles, etc. in the produced fluid also decrease. This leads to poorer demulsification, flocculation and other effects and a decline in treatment efficiency. For example, in winter or cold regions, the temperature of the produced fluid is low. When using 40%chemical polydadmac emulsion for treatment, it may be necessary to increase the dosage of the reagent or extend the treatment time to achieve better results. 2.Room-temperature conditions: At room temperature, polydadmac coagulant can exert a relatively stable treatment effect. Under the general ambient temperature, the molecular structure and performance of polydadmac 40 are relatively stable and can interact with substances in the produced fluid as expected to achieve treatment goals such as demulsification, flocculation and impurity removal. Studies of chemical polydadmac products have shown that the aqueous solution of polydadmac chemicals is relatively stable in the pH range of 0.5-14 at room temperature. 3. High-temperature conditions: Appropriate increase in temperature can enhance the treatment effect of polydadmac coagulant. When the temperature rises, the molecular movement intensifies, and the contact and reaction of polydadmac 40 with each component in the produced fluid become more sufficient. The demulsification and flocculation speeds increase and the treatment efficiency improves. However, if the temperature is too high, it may cause adverse reactions such as thermal decomposition of polydadmac chemicals, affecting the treatment effect of chemical polydadmac products and even possibly damaging the molecular structure of 40%chemical polydadmac emulsion and causing it to lose its treatment ability. Overall, within a certain temperature range, the treatment effect of polydadmac coagulant improves with increasing temperature. However, both excessively high and low temperatures have adverse effects on the treatment effect of polydadmac 40. The specific optimal temperature range may vary depending on the specific properties of the produced fluid, the treatment process and the formulation of polydadmac 40, etc.

40%polydadmac and 50%polymine products always used for industrial wastewater and sewage treatment.

Industry-specific attributes

| Name | Polydadmac 40 chemical polydadmac products | |||

| Molecular Formula | (C8H16NCl)n | |||

| Application | Water Treatment | |||

Other Attributes

| Appearance | Colorless to white liquid,transparent | |||

| Odor | Odorless | |||

| Content | 40% | |||

| Viscosity,cPs | 6000~100000 | |||

| PH Value | 5~8 | |||

| Shelf life | 24 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |