CPAM Emulsion For Water Treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

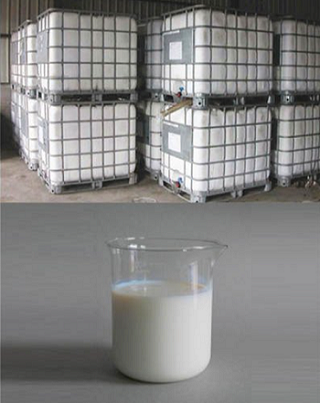

1.Every month our factory could produce 2000tons CPAM liquid and liquid CPAM product is a cross linked polymer.

2.We have cooperated with more than 300 clients in CPAM for water treatment project.

3.We own dozens of outstanding engineer and customized products could be supplied in emulsion CPAM water treatment.

Download

The shelf life of CPAM liquid can be prolonged through the following methods:

1. Controlling the storage environment for storing CPAM liquid.

1)Temperature: Cationic liquid flocculant should be stored in a cool place and the ideal storage temperature is between 5℃ and 30℃. High temperatures will accelerate the degradation and deterioration of the CPAM liquid product, reducing the performance of liquid CPAM product. For example, during high temperatures in summer, if the liquid CPAM product is placed in direct sunlight, the temperature may exceed 40℃, which will significantly shorten the shelf life of the product. You can choose to store the product of cationic liquid flocculant in basements, warehouses and other places with relatively stable temperatures and avoid proximity to heat sources such as heating equipment and heaters.

2)Humidity for storing cationic liquid flocculant: Keep the storage environment dry and the relative humidity is preferably controlled below 60%. A high humidity environment easily causes the product of CPAM liquid to absorb moisture, thereby affecting the performance and stability of liquid CPAM product. For example, storing the emulsion CPAM water treatment product in a damp basement may cause the CPAM liquid product to absorb moisture from the air, resulting in the emulsion becoming thinner, undergoing hydrolysis reactions, etc.Desiccants or dehumidification equipment can be used to reduce the humidity of the storage environment to ensure the liquid CPAM product does not get damp.

2.Ensuring packaging sealability of emulsion CPAM water treatment product.

1) Choosing the appropriate packaging for storing CPAM liquid. Use packaging containers with good sealing properties, such as plastic buckets to ensure the packaging is intact and leak-free. High-quality packaging materials can effectively block the entry of air, moisture and light, protecting the quality of the CPAM for water treatment product. For large-capacity packaging, consider adding inner bags or sealed lids to further improve the sealing of the packaging.

2) Checking the integrity of the packaging: During storage and use cationic liquid flocculant, regularly check the sealing of the packaging. If any damage, leakage, or deformation of the packaging is found, the packaging should be replaced or remedial measures taken in a timely manner. For example, sealant can be used to repair small damages. For severely damaged packaging, the CPAM liquid product should be transferred to a new sealed container.

3. Avoid having the liquid CPAM product contact with other substances.

1) Prevent having emulsion CPAM water treatment product contact with metals: CPAM liqiud should avoid contact with metals such as iron and copper, as metal ions may react with the product, affecting the performance and stability of CPAM liquid. For example, during storage and transportation, do not use metal containers or tools to hold and stir the product of CPAM liquid.

2) Keeping away from oxidizing agents and reducing agents: Oxidizing agents and reducing agents will undergo chemical reactions with liquid CPAM product, destroying the molecular structure and reducing the performance of the CPAM for water treatment product. For example, oxidizing agents such as hydrogen peroxide and potassium permanganate, and reducing agents such as sodium sulfite and sodium thiosulfate should all be kept away from the product storage area. During storage and use liquid CPAM product, ensure there are no such substances around the product to avoid accidental reactions.

4.Correct usage and handling for cationic liquid flocculant

1) Following the usage instructions: When using CPAM liquid, strictly follow the usage methods and dosages in the CPAM liquid product manual. Avoid excessive or incorrect usage to prevent emulsion CPAM water treatment product waste and performance degradation. Pay attention to the usage sequence and mixing methods to ensure the CPAM for water treatment product can fully exert its effect while reducing quality issues caused by improper usage.

2). Promptly handling remaining products of CPAM liquid: If there is remaining liquid CPAM product, it should be sealed and stored in a timely manner and used as soon as possible. Do not expose the remaining product of cationic liquid flocculant to the air for a long time or store CPAM for water treatment product mixed with other substances.For expired or deteriorated product of CPAM liquid, they should be properly disposed of in accordance with environmental protection requirements and not discarded randomly to avoid pollution to the environment.

Industry-specific attributes

| Name | CPAM liquid | |||

| Application | CPAM for water treatment | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes

| Appearance | White Emulsion | |||

| Activate Content | 48% | |||

| Viscosity Range(ml/g) | 1200~1600 | |||

| Residue | 0.12% | |||

| Insoluble Substance(%) | 0.1 | |||

| Cationic Charge | 80% | |||

| Dissolving Time,min | 40 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 12 | |||

Supply Ability

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |