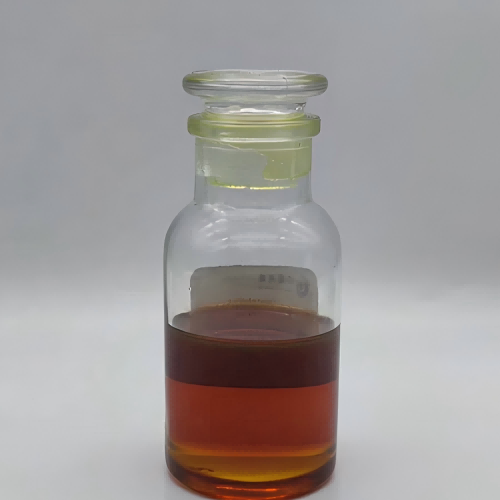

Demulsifier

Brand Shenyang Jiufang

Product origin China

Delivery time Lead time: 7days

Supply capacity 10000MT/Year

As a demulsifier of supplier in China, Jiufang Tech produces the demulsifier for oilfield crude treatment.

Jiufang Tech has focused on the customizing demulsifier product for over 20years and supply demulsifier for oilfield can meet various properties of crude.

Download

The demulsification principles of demulsifier emulsion dewatering are:

1.Phase transfer--Reverse transformation mechanism After adding the demulsifier product, a phase transformation occurs: Surfactants that can form an emulsion type opposite to the emulsion formed by the emulsifier can act as demulsifier product. Such demulsifier product easily form complexes with emulsifiers, causing the emulsifiers to lose their emulsifying properties.

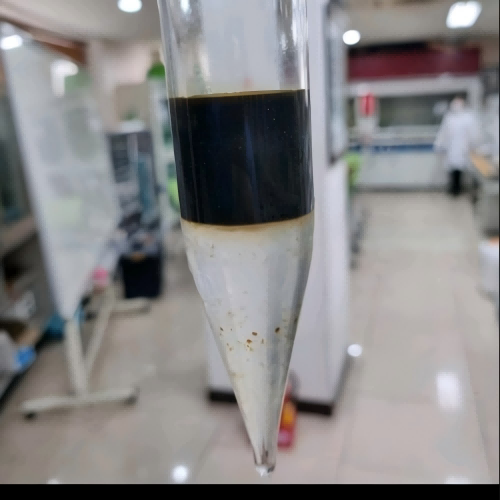

2.Flocculation--Coalescence demulsification mechanism Under the conditions of heating or stirring, demulsifier for oilfield have more opportunities to collide with the interface film of the emulsion or adsorb on the interface film, or displace some surface active substances, thereby breaking the interface film and greatly reducing its stability, resulting in flocculation, coalescence and demulsification.

3.Solubilization mechanism One molecule or a few molecules of the used demulsifier emulsion dewatering can form micelles. Such polymer coils or micelles can solubilize emulsifier molecules, causing the emulsified crude oil to demulsify.

4.Neutralizing the charge of the interface film for demulsification mechanism The droplet surface of 0/W type emulsions carries negative charges. Cationic polymers have effects such as neutralizing the interface charge, adsorbing and bridging and flocculating and coalescing on 0/W type emulsions, therefore they have good demulsification performance.

Not only do we supply demulsifier, but we also provide related technical support for the end users.

Incorrect use of demulsifier emulsion dewatering can cause the following hazards:

1) It increases the power consumption during the transportation process and the volume of the liquid flow.

2) It reduces the effective utilization rate of equipment and pipelines, increases the fuel consumption in the heating process and causes scaling and corrosion of pipelines and equipment.