Demulsifier For Crude Dehydration

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

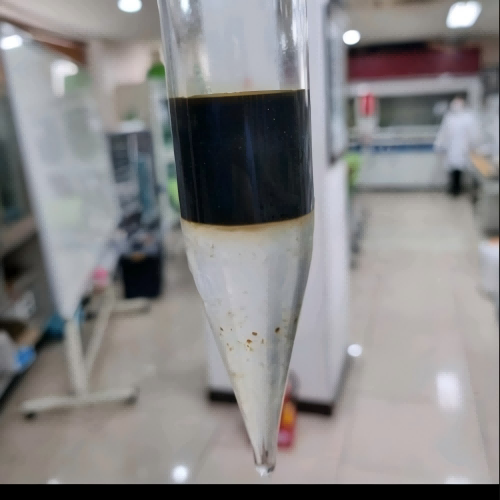

1. Crude in demulsifier means using demulsifier to separate water from crude.

2. Oily sludge emulsion breaker is a type of additive chemical in pretreatment process.

3. Demulsifier for oilfield is a form of crude in demulsifier which is ethylene oxide and propylene oxide block polyethers

Download

Ethylene oxide and propylene oxide block polyethers are a type of important compound of demulsifier for oilfield and have wide applications in multiple fields.

As the main raw material of crude in demulsifier, ethylene oxide and propylene oxide block polyethers are block copolymers formed by the ring-opening polymerization of two monomers, ethylene oxide (EO) and propylene oxide (PO).

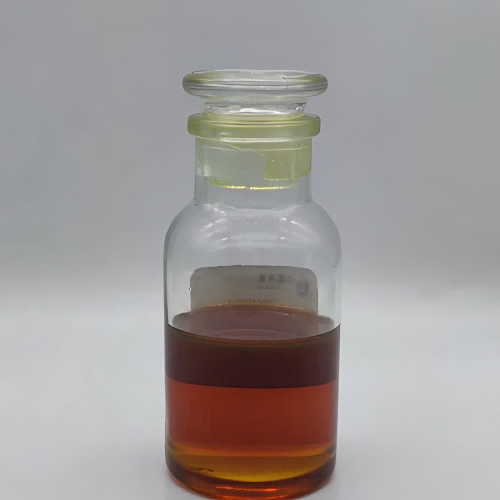

The molecular structure of demulsifier for oilfield contains hydrophilic EO segments and hydrophobic PO segments. This unique structure of oily sludge emulsion breaker gives them amphiphilic properties, that is, demulsifier for oilfield have both hydrophilicity and lipophilicity. Different block polyethers with different properties can be synthesized according to the ratio of EO and PO and the sequence of blocks. For example, when the content of EO is higher, the hydrophilicity of the polyether is enhanced; while when the content of PO is higher, the hydrophobicity of the polyether is enhanced. Ethylene oxide and propylene oxide block polyethers are usually colorless or light yellow liquids with low viscosity and surface tension. Demulsifier for industrial use have good solubility in water and can form transparent solutions. At the same time, due to demulsifier for oilfield hydrophobic PO segments, demulsifier for oilfield can also dissolve or disperse in the oil phase. The polyethers of oily sludge emulsion breaker have good thermal stability and do not decompose within a certain temperature range. Oily sludge demulsification also have certain acid and alkali resistance and can remain stable within a wide pH range. Ethylene oxide and propylene oxide block polyethers are a commonly used type of demulsifier for oilfield. Due to the amphiphilic structure of oily sludge demulsification, oily sludge emulsion breaker can adsorb on the oil-water interface, reduce the interfacial tension, destroy the stability of the emulsion and promote the separation of oil and water.

Block polyethers with different structures have different oily sludge demulsification effects on different types of crude in demulsifier. By adjusting the ratio of EO and PO and the length of the blocks, efficient demulsifier for oilfield suitable for specific oilfields can be designed. For example, for high-water-cut crude oil, block polyethers with stronger hydrophilicity can be selected; while for heavy crude oil, block polyethers with stronger hydrophobicity can be selected. At the same time, in the tertiary oil recovery of oilfields, ethylene oxide and propylene oxide block polyethers can be used as oil-displacing agents. Crude in demulsifier can reduce the oil-water interfacial tension and improve the recovery rate of crude oil.

Due to demulsifier for industrial use good solubility and stability, crude in demulsifier can remain active in the oil reservoir for a long time. Compared with other oil-displacing agents, block polyethers have the characteristics of low toxicity and environmental friendliness and do not cause serious pollution to the formation.

In addition, crude in demulsifier can also be compounded with other chemicals to improve the oil-displacement effect.

Industry-specific attributes

| Name | Oily sludge demulsification | |||

| Items | Indicator | |||

| Application | Demulsifier for industrial use | |||

Other Attributes

| Appearance | Yellow to Brown liquid,no impurities | |||

| Odor | Slightly Odorless | |||

| Density (20°C ) | 1.1- 1.25 g/ml (9.51-9.85 lb/gal) | |||

| Content | >35% | |||

| Viscosity (20°C ) | < 150cp | |||

| PH (20°C) | 3~6 | |||

| Freezing point | 12°C (10°F) | |||

| Boiling point | 99 °C (210°F) | |||

| Solubility in water | Soluble,easily dispersible | |||

| Closed flash point,℃ | ≥93.3 | |||

| Shelf life | 12 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |