Industrial Polydadmac Product For Crude Oil Treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

1.We could produce 1000tons industrial grade polydadmac per month which is polydadmac product for crude oil.

2. Polydadmac product for crude oil is used for pre-dehydration of crude oil treatment.

3. Because of polydadmac material, all of the polydadmac can meet drinking and industrial grade polydadmac

Download

Methods to improve the effect of polydadmac product for crude oil and other aspects:

1. Compound with other agents: Combine with different types of demulsifiers. For example, combine non-ionic demulsifiers with industrial grade polydadmac for crude oil and utilize the lipophilic and hydrophilic properties of non-ionic demulsifiers and the cationic properties of polydadmac to synergistically exert the demulsification effect and improve the treatment effect on complex produced fluids.

Combine with flocculants. Select the appropriate flocculant to cooperate with industrial grade polydadmac, which can enhance the flocculation effect on solid particles and suspended substances in the produced fluid and accelerate the sedimentation and separation process. For instance, the combined action of inorganic flocculants such as polyaluminum chloride and polydadmac can form larger and tighter flocs and improve the separation efficiency. Add coagulant aids. Coagulant aids can improve the structure and sedimentation performance of flocs. For example, the combined use of coagulant aids such as polyacrylamide and polydadmac can make the flocs more stable and less prone to breakage, thereby improving the treatment effect.

2. Adjust the concentration and ratio of the agents: Determine the optimal concentration of industrial grade liquid polydadmac through experiments. Conduct jar test and pilot-scale tests for different characteristics of the crude oil to find the optimal concentration range that can ensure the treatment effect and avoid waste of the agent. For example, for crude oil with high oil content and high viscosity, the concentration of polydadmac may need to be appropriately increased. Optimize the ratio of the compound agents. Adjust the ratio of industrial grade liquid polydadmac to other agents according to the specific situation of the crude oil to achieve the best synergistic effect. For example, by changing the ratio of industrial grade liquid polydadmac to demulsifiers, observe the changes in the demulsification effect and the speed of oil-water separation to determine the optimal ratio.

3. Optimize the process flow: Adjust the treatment sequence. Arrange the addition position and sequence of polydadmac product for oil in the treatment process reasonably according to the properties of the crude oil and the treatment requirements. For example, preliminary physical separation, such as sedimentation or filtration, can be carried out to remove larger particle impurities first, and then industrial grade polydadmac is added for demulsification and flocculation treatment to improve the utilization rate and treatment effect of the agent. Add pretreatment links. Before the crude oil enters the main treatment process, conduct pretreatment, such as heating and adjusting the pH value. Heating can reduce the viscosity of the crude oil and improve the contact and reaction speed of polydadmac product for crude oil treatment with oil droplets; adjusting the pH value can enable industrial grade liquid polydadmac to function in a more suitable environment. Adopt multi-stage treatment. For crude oil that are difficult to treat, a multi-stage treatment process can be adopted and an appropriate amount of industrial grade polydadmac and other agents are added at different treatment stages to gradually improve the treatment effect. For example, conduct the first-stage demulsification and flocculation treatment to remove most of the oil and suspended substances and then conduct the second-stage advanced treatment to further improve the water quality.

4. Improve equipment and operating conditions: Select the appropriate stirring method and intensity. Stirring can promote the full mixing of polydadmac product for crude oil treatment and the crude oil, but excessive stirring intensity may damage the flocs. Adopt an appropriate stirring method, such as slow stirring or intermittent stirring, and adjust the stirring intensity according to the actual situation to ensure that the agent and the crude oil are uniformly mixed without damaging the structure of the flocs. Control the treatment temperature and time. Determine the optimal treatment temperature and time based on the characteristics of industrial grade liquid polydadmac and the properties of the crude oil. At an appropriate temperature, the molecular movement of industrial grade polydadmac accelerates and the reaction activity improves, resulting in a better treatment effect. At the same time, reasonably control the treatment time to avoid the influence of too long or too short treatment time on the treatment effect.

Optimize the operating parameters of auxiliary treatment equipment such as air flotation and filtration. During the air flotation treatment process, adjust parameters such as bubble size, gas flow rate and flotation time to improve the removal effect of flocs and oil droplets; in the filtration link, select the appropriate filtration medium and filtration pressure to ensure the filtration effect and extend the service life of the filtration equipment.

Industry-specific attributes

| Name | Industrial grade liquid polydadmac | |||

| Technical data | Supply polydadmac COA | |||

| Application | Polydadmac product for crude oil treatment | |||

Other Attributes

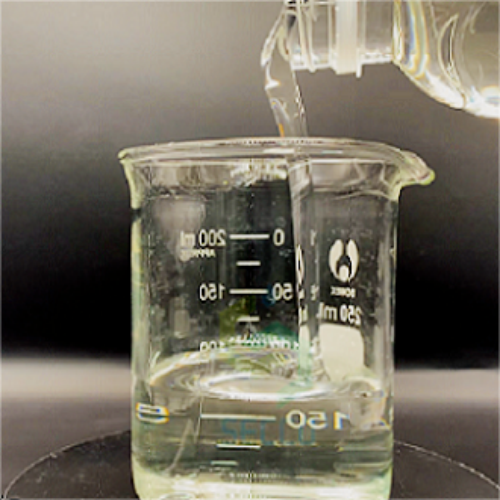

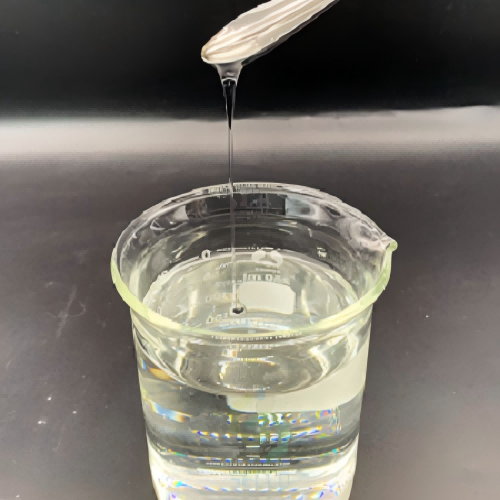

| Appearance | Colorless to white liquid,transparent | |||

| Odor | Odorless | |||

| Content | 40% | |||

| Viscosity,cPs | 6000~100000 | |||

| PH Value | 5~8 | |||

| Shelf life | 12 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |