Polydadmac For Oily wastewater Treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

1.Chemical polydadmac for oil treatment is in the pre-dehydration process and it is very important for the next process.

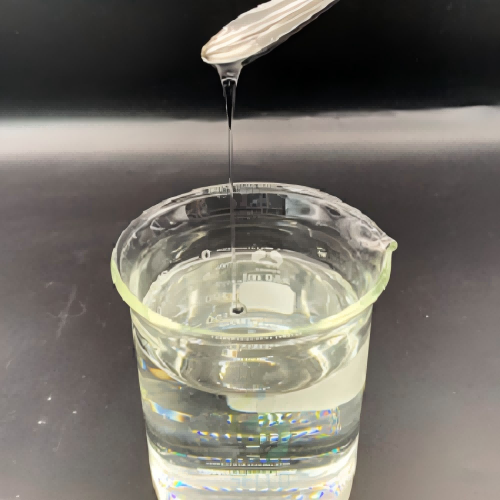

2. Oil treatment polydadmac is a high molecular weight and strong cationic charge product.

3. As a polydadmac powder and liquid suppliers, we can customize various content and form polydadmac: polydadmac liquid& polydadmac powder.

Download

The process parameters of treating oily wastewater with polydimethyldiallylammonium chloride (Polydadmac) mainly include the following aspects:

1. Polydadmac powder and liquid dosing parameters, mainly including:

1). Dosage: Generally, the dosage of polydadmac powder and liquid is between 10--100mg/L. The specific dosage of oil treatment polydadmac needs to be adjusted according to the characteristics of the oily wastewater, such as oil content, suspended solids content, pH value, etc. For wastewater with a high oil content, a large amount of suspended solids or complex water quality, the dosage of oil treatment polydadmac may need to be appropriately increased. While for wastewater with a low oil content and good water quality, the dosage of oilfield polydadmac can be appropriately reduced to lower the cost.

2).Dosing point: Usually, polydadmac powder and liquid is added to the mixed reaction tank of oily wastewater to fully mix with the wastewater. The dosing point of oilfield polydadmac powder should be selected at a position where the water flow is relatively stable to avoid the chemical being washed away rapidly by the water flow and unable to fully exert the effect of chemical polydadmac for oil treatment. Polydadmac powder and liquid can also be added at other positions in the wastewater treatment process according to the actual situation, such as in the pretreatment stage or the entrance of the air flotation device.

2. Mixing and reaction parameters of oil treatment polydadmac.

1). Stirring speed: The stirring speed has an important influence on the mixing effect and flocculation reaction of chemical polydadmac for oil wastewater. Generally, the stirring speed is between 50 - 200r/min. An excessively high stirring speed may destroy the formed flocs and reduce the treatment effect of polydadmac powder or liquid; while an overly slow stirring speed may lead to uneven mixing of the polydadmac powder or liquid and wastewater, affecting the progress of the flocculation reaction.

2).Reaction time: The reaction time of oil treatment polydadmac powder is generally between10-30 minutes. A too short reaction time may result in incomplete flocculation reaction and poor treatment effect; an overly long reaction time may increase the treatment cost and equipment footprint.

3. When using oilfield polydadmac,air flotation patamters mainly include:.

1). Bubble size: During the air flotation process, the bubble size should be controlled between10--100μm. Smaller bubbles can provide a larger specific surface area, increase the contact opportunity with the flocs and improve the air flotation effect. The bubble size can be controlled by adjusting factors such as the intake pressure of the air flotation equipment and the type of bubble generator.

2). Air flotation time: The air flotation time is generally between10--30 minutes. If the air flotation time is too short, the flocs may not have enough time to fully combine and float with the bubbles, resulting in incomplete treatment; if the air flotation time is too long, it may increase energy consumption and equipment operation cost.

3). Gas flow rate: The gas flow rate should be adjusted according to the treatment volume and water quality of the oily wastewater. Generally, the gas flow rate is between 0.5 - 2m³/h·m² (gas flow rate per square meter of the air flotation tank area). A too low gas flow rate will lead to poor air flotation effect, while an excessively high gas flow rate may destroy the flocs and affect the treatment effect.

4. When using chemical polydadmac for oil treatment, the sedimentation parameters mainly include:

1). Sedimentation time: The wastewater after air flotation treatment usually needs to undergo sedimentation to further remove the remaining suspended solids and flocs. The sedimentation time is generally between1--2 hours. If the sedimentation time is too short, when using oil treatment polydadmac,some suspended solids and flocs may not fully sediment, affecting the effluent water quality; if the sedimentation time is too long, it may increase the treatment cost and equipment footprint.

2). Sludge discharge cycle: As the sedimentation process progresses, a certain amount of sludge will accumulate at the bottom and needs to be discharged regularly. The sludge discharge cycle is generally determined according to the accumulation rate of the sludge and the treatment volume, usually between1--2 days. Inadequate and untimely sludge discharge may lead to excessive sludge accumulation, affecting the sedimentation effect and the normal operation of the equipment.

5. When using chemical polydadmac for oil treatment, other parameters mainly include:

1). pH value: The suitable pH range for oilfield polydadmac to treat oily wastewater is generally between 6--9. Within this range, the flocculation effect of the oilfield polydadmac is good and at the same time, it can ensure that the water quality after oilfield polydadmac treatment meets the discharge requirements. If the pH value of the wastewater is not within this range, it can be adjusted by adding acid-base regulators.

2).Temperature:Temperature also has a certain influence on the treatment effect of polydadmac powder or liquid. Generally, at room temperature (20--30℃), oilfield polydadmac can exert a good flocculation effect. For wastewater with a high or low temperature, appropriate insulation or cooling measures can be considered to ensure the stability of the treatment effect.

Industry-specific attributes

| Name | Polydadmac powder and liquid | |||

| Molecular Formula | (C8H16NCl)n | |||

| Application | Oil treatment polydadmac | |||

Other Attributes

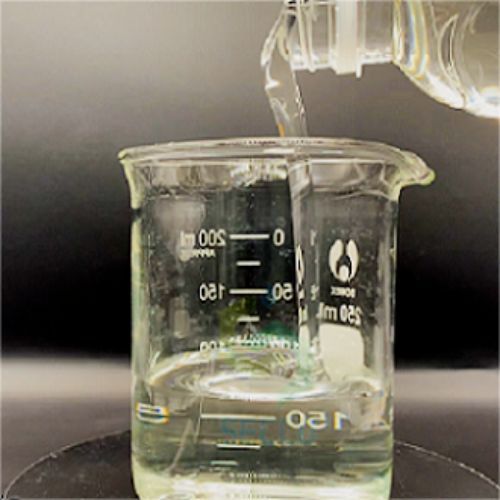

| Appearance | Colorless to white liquid,transparent | |||

| Odor | Odorless | |||

| Content | 40% | |||

| Viscosity,cPs | 6000~100000 | |||

| PH Value | 5~8 | |||

| Shelf life | 12 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||